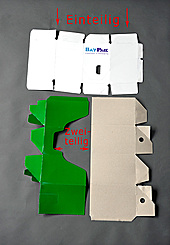

Comparison 1-piece versus 2-piece packaging

Consideration of sustainability begins much earlier, however, long before the actual production process - printing, die-cutting, gluing. This becomes very clear with the comparison which we drew up for the meat self-service shelf market. The table below compares the eco-balance or the consumption of resources of 1-piece packages and 2-piece packages.

Eco-balance comparison 1-piece vs. 2-piece (basis 10,000 outer packages = 10 t sausage)

| Consumption of resources | 1-piece | 2-piece | Additional consumption for 2-piece in % |

| Raw material | 1,549 kg | 2,071 kg | 33.7% |

| Power | 465 kwh | 622 kwh | 33,8% |

| Gas | 282m³ | 377m³ | 33,7% |

| Waste paper | 1,850 t | 2,485 t | 34,3% |

| Water | 6.97m³ | 9.32m³ | 33,7% |

| Production costs | |||

| Printing, die-cutting, gluing | 3.95h | 6.25h | 58,2% |

| Power | 98.8 kwh | 156.3 kwh | 58,1% |

| Freight costs | |||

| Uncoated cardboard and finished product | 19.9 l diesel | 39.72 l diesel | 100% |

| Pollutant emissions | |||

| CO Carbon monoxide | 541.8g | 1,084g | 100% |

| HC Hydrocarbons | 103.2g | 206.4g | 100% |

| NOX Nitrogen oxide | 3,458g | 6,916 g | 100% |

| Source: own research |

| The top priority in the Development department at BayPack is to make the box designs as efficient as possible, i.e. to minimise the cardboard surface required for the box. This is achieved with economical cuts, smallest possible gluing areas, minimum use of material-intensive tuck-in flap and above all use of 1-piece designs. With 1-piece designs, the complete packaging is made from one piece of cardboard, in contrast to 2-piece base/lid designs. Due to double wall thicknesses, closed wall surfaces and often crash-lock base designs with lids, the 2-piece designs require considerably more material. | ||||

| If the production and freight costs and the pollutant emissions produced are taken into consideration as well, the eco-balance is clearly better for 1-piece designs (see figures). |  | |||

|  | |||

The consideration of freight and warehouse costs is also particularly important here. BayPack works mainly with the raw materials full and compact cardboard, which is characterised by its low volume and simultaneously high resistance to stacking compression. Supplied pallets with one-piece boxes made of full or compact cardboard are, for example, loaded much higher (more packages/pallet) than pallets of a similar box design consisting of a base and lid. In addition, when it comes to transport and use, always 2 pallets (1x base, 1x lid) are required, but only 1 pallet with a 1-piece design. 50 % less pallet storage space is therefore required in the packaging warehouse. Already on delivery, this results in lower freight costs and charges and is also reflected in lower warehousing and administration costs (simplified inventory management, fewer article numbers etc...) .

Also for the individual finished products, packed in 1-piece designs, Euro or industrial pallets are better utilised due to the thin wall thicknesses of the full and compact cardboard and fewer pallets are therefore transported by road.

In addition, 1-piece packaging with low space requirements has the attractive additional benefit that it is lower in cost. Why? Firstly, the material costs make up 50 % of the sales price on average and, secondly, the small cardboard surface is an important cost factor thanks to the higher number of prints per sheet in the printing and cutting processes.

The trade also has 'sustainable' advantages with 1-piece BayPack packaging. Usually the packages are provided with opening systems (reverse scoring technology), which can be opened easily and cleanly and allow perfect shop presentation. We ensure here that only small, flat tear-off or opening residue remains and therefore has to be disposed of. Therefore less waste here too.

This guarantees sustainability throughout the supply chain and advantages for the environment and all those involved.

Packaging from BayPack - a model example of absolutely sustainable, ecologically-based and produced packaging!

Contact

![]() +49 (0) 8261 73111-0

+49 (0) 8261 73111-0

![]() +49 (0) 8261 73111-50

+49 (0) 8261 73111-50

![]() BayPack GmbH

BayPack GmbH

Bahnhofstraße 30

D-87778 Stetten